This linear carriage design is something I have been toying with for several years now.

It all started with having picked up a bulk lot of 608zz skate bearings with the intent of making a Rostock or similar delta printer some day, but mostly because I needed a few for my Mendel and at 30 cents a bearing for a hundred bearing I felt I couldn’t pass it up – I’d find a use for them.

I was actually working on the early proof of concepts for the K02 corexy printer I wanted to build when I came up with the idea of turning the square tubing 45 degrees. I had picked up some stock aluminum 3/4″ tubing at the hardware store to play around with and was trying to work out a simple method of utilizing them as both the frame and the linear guide using the skate bearings.

The main challenge was that the bearings need to be preloaded to an extent and most methods of getting them tensioned against the tube and constrained well enough to function as a linear guide required a great number of bearings. Such a mechanism gets quite large when dealing with skate bearings and typically requires less common bearings that are smaller.

I have no record of how long I spent just rolling bearings in various configurations along the aluminum stock and daydreaming until I stumbled across this trick, which I believe is unique to myself, of pinching an edge of the tube between two skate bearings to form a point on the linear guide. I recall that I printed various small plastic parts to test my various ideas which was an introduction to designing custom parts in SketchUp as well as proving the usefulness of rapid prototyping that can be achieved with a 3D printer. Any idea I had could be test implemented within a matter of minutes or at worst hours depending on the size of the part.

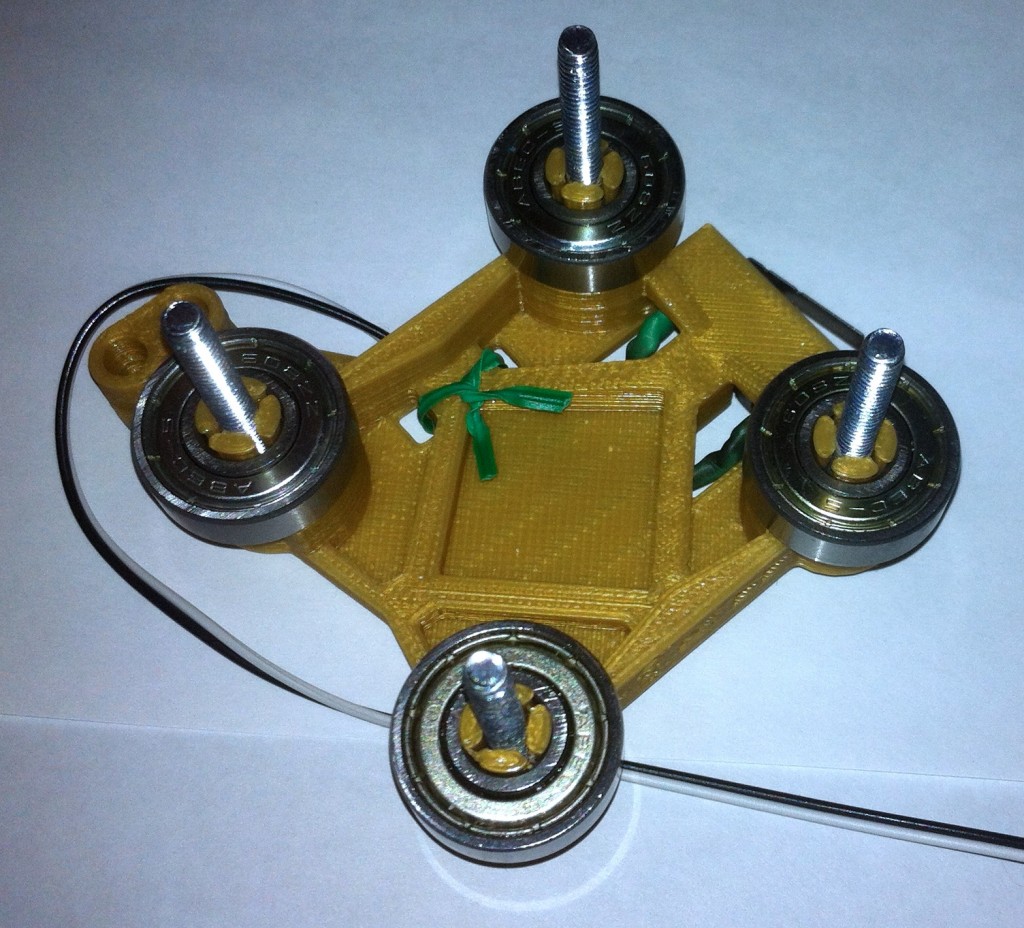

I quickly whipped up a linear carriage design that used three bearings mounted on a plate and a mirror of that held together with four bolts to form the linear carriage. I expanded on this and built a corexy stage with crude but workable filament drive made from reinforced fishing line.

This is an early prototype of the design, intended to be used with a CoreXY mechanism:

It worked fairly well and was able to plot out shapes reasonably accurate from g-code output from Slic3r. I had some initial concerns about the longevity of the soft extruded aluminum tubing verses the hardened steel edges of the skate bearings, as did those I shared the concept with on the #reprap irc channel.

After about 10 hours of running the mechanism it became apparent that the bearings tightened down to the point they’d be accurate linear mechanisms was eating deep gouges into the tubing and would need to be constantly tightened (by pulling the plates closer together) until there was going to be no tubing left.

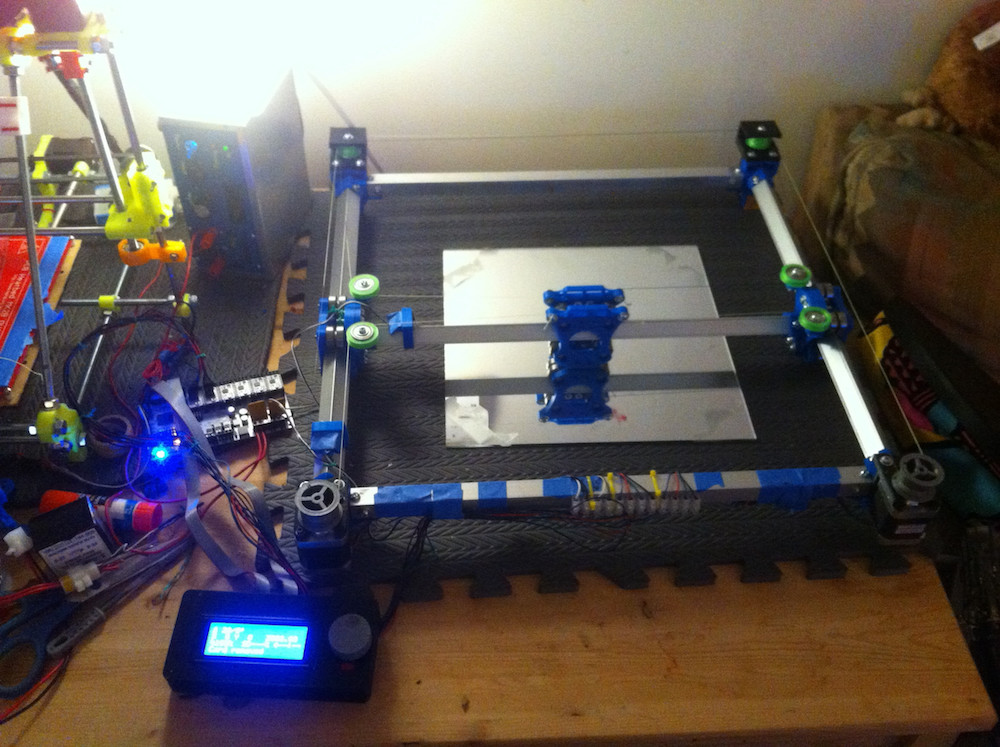

Here is a picture of an early test build of the design:

There are issues with the overall CoreXY mechanism shown, there are non parallel drive lines at the rear which would cause accuracy issues over the course of a print. It’s running on a RUMBA controller board and powered by my home made 12v lab supply, sitting beside an earlier build of my trusty Mendel. This is early in the testing and the aluminum tubing has yet to be eaten by the carriages. I’d already switched from a 3-per-side bearing system to a 4-per-side bearing system by this point to deal with binding issues caused by the stresses of the tensioned drive mechanism.

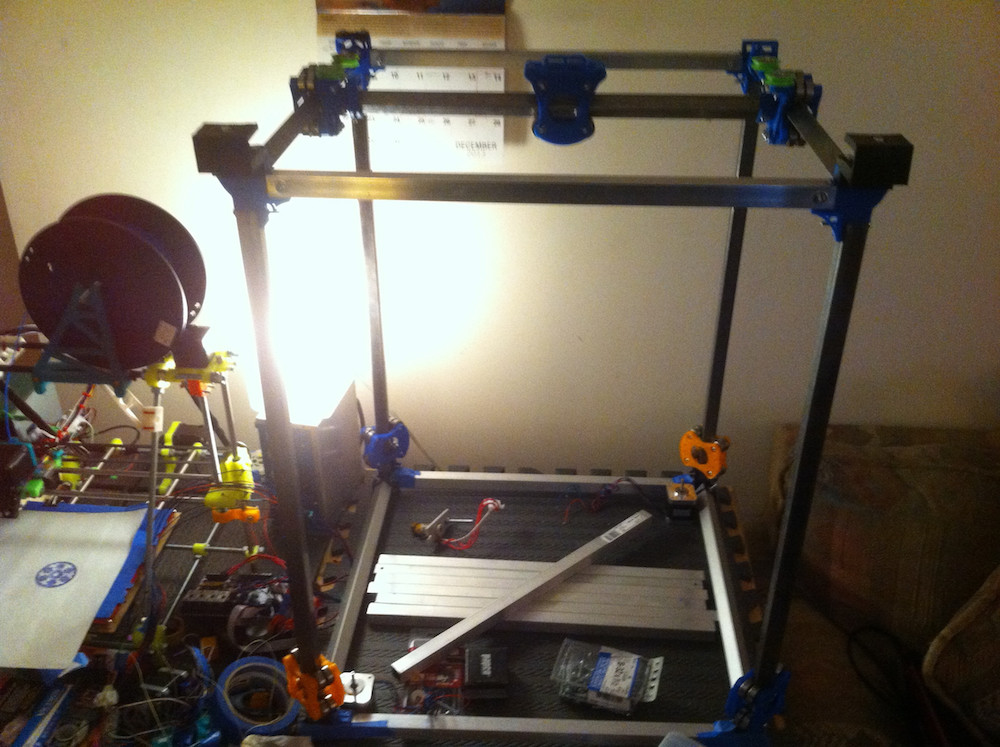

Work proceeded rapidly and by December of 2013 I had the above mechanism in place with steel tubes instead of aluminum on the moving axises and some ideas as to how to attempt a Z axis. The drawing on the piece of paper sitting on the Mendel’s bed was done by the steel version of the gantry and shows how much this concept dwarfed it.

I got so far as to mocking up a few Z axis designs for the CoreXY before I finally had to admit a bit of defeat that the moving weight of the carriages and the steel cross bar, as well as the Z axis variations were not going to meet my goals of a fast large format 3D printer. It worked, but it was going to be a slow machine – and I was not entirely convinced the simple filament drive system was going to be accurate without some serious reconsiderations. This project had started in late 2013 and I had started to question of the wisdom of filament drives in spring of 2014. GT2 timing belts were only just starting to flood the market, there were a lot of us playing with filament drives up to that point and running into certain concerns about positional accuracy with the windings on the spools. Timing belts were becoming cheap enough that the price was comparable to fishing line that was strong enough for RepRap usage and comes with easier repeatable motion.

I had one last concept to try before I gave up on the big CoreXY machine – I wanted to make the carriages thin and remove the extra washers that I had been using as spacers between the two halves of the carriage. Above is a prototype of a snap-fit bearing holder system with an integrated end-stop and drag chain holder. This was not easy to design in SketchUp and I started to consider learning OpenSCAD around this time. The snap fit bearing holders were also a bust – the bearings really need to be constrained around their hubs from both sides in order to make this system work. Since it’s a unique concept, I wouldn’t have known unless I tried.

I decided there was going to have to be a better way to build a CoreXY printer, but thought the linear carriage would be particularly suited to a Delta style printer mechanism. Below is a side-by-side comparison of how the K02 mechanism became the K03 mechanism that I was using for the past 2 years. (right to left)

The final version on the left turns out to not be that final. It was an exercise in minimalism which carried onto my next project, the very first version proof-of-concept version of the Gemini 3D printer. Much like the first Gemini build, it proved that you can indeed building things too thin with plastic. The linear mechanism shown above did work for a time, but the printer ran into other problems and I got focused on other things, such as the Gemini.

It’s worth noting that the leftmost mechanism was still in place in the past week when I got the K03 Delta running again. Only the swivel and adapter portion were replaced.

Recent Comments