It’s been a busy week so I’ve not had time to detail my progress, but my K03 – Kitchissippi Delta 3D Printer is back up and running and better than ever with the newly designed OpenSCAD parts.

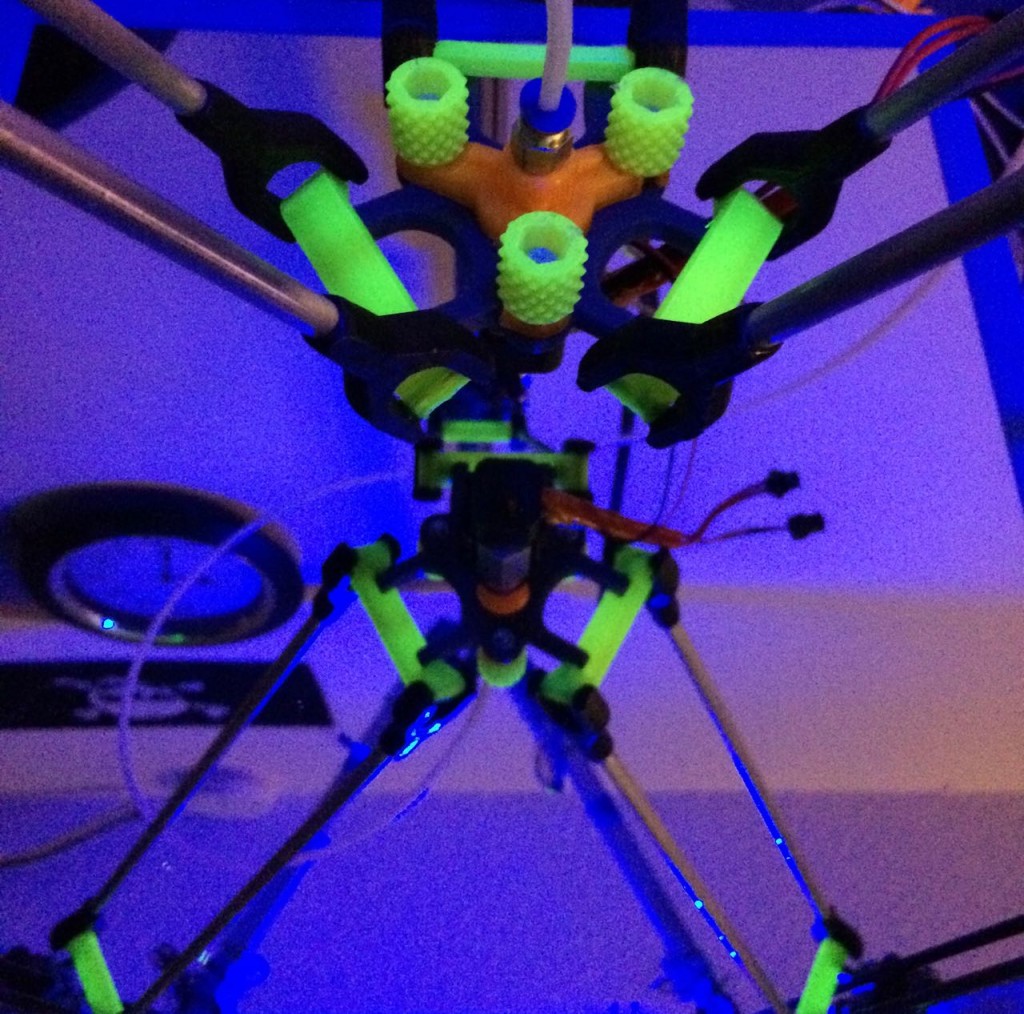

Here is the new effector assembled with the new swivel joints and push fit bowden connector, currently working with a Hexagon hotend:

It works quite well, I am suitably impressed at what the machine can do and it’s printing speeds and quality.

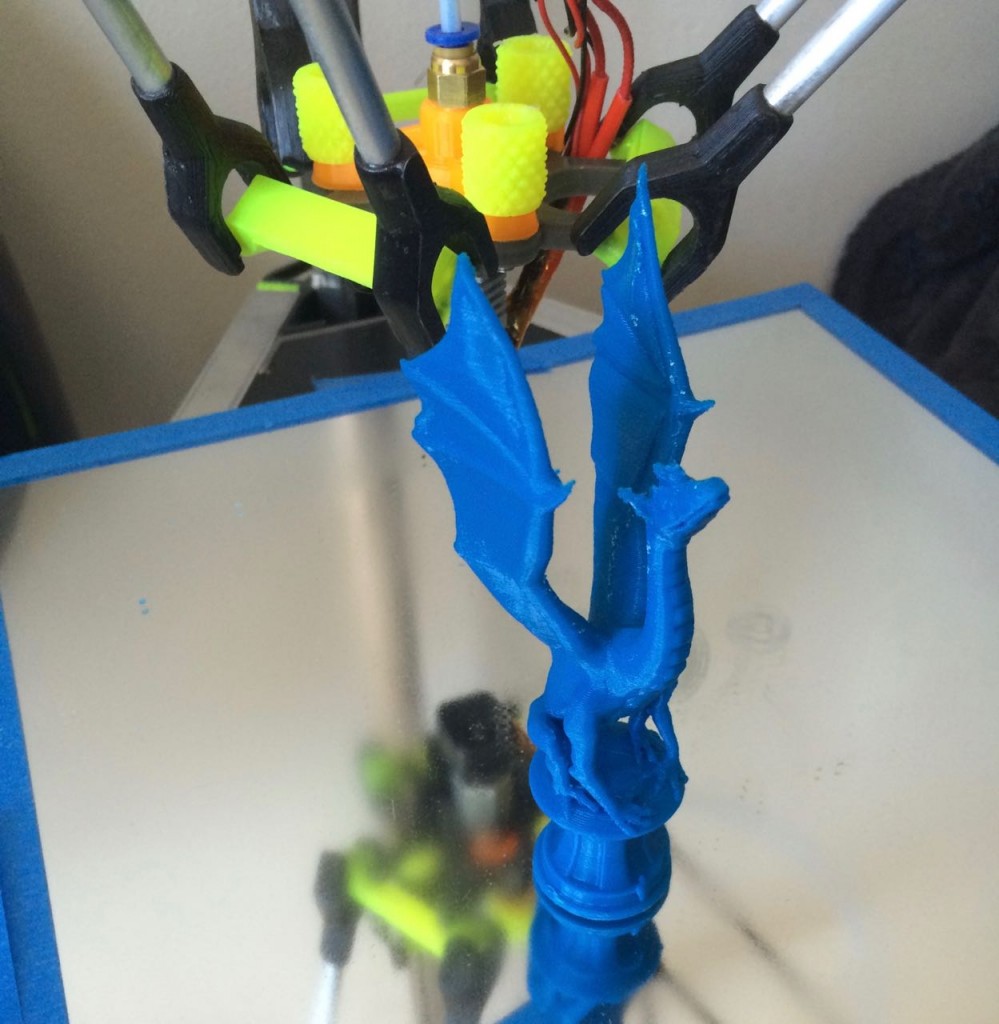

The above dragon was made with ABS and was my first major print since getting the machine calibrated.

I am fairly happy with the workings of the machine, although there is definitely room for improvement.

As a side project which is related to the needs of both the Kitchissippi Delta and the Gemini 3D printer, I designed a new bowden extruder system. Most of the filament pushers I found online where lacking in some way – either they didn’t use bearings that I have on hand (I have a LOT of 608zz bearings that I got for quite cheap) or they used what I felt to be an excessive amount of hardware. One big factor is that the push fit connectors I have on hand are all 3/8″ thread diameter with no internal guide path for the filament.

These connectors necessitate a larger hole than anyone else is using as well as a 3D printed guide to hold a short length of PTFE tube inside the connector to allow for smooth filament transmission.

This is the basic mechanism I came up with – it works well, even in it’s current rough design state:

I have one of these zip-tied to the frame with a slightly too-long length of PTFE tube and it has been working very reliably for about 20 hours so far with ABS plastic. I’ve not tried it on PLA just yet as I’ve had some issues with the Hexagon and non-ABS plastics. I don’t see any particular reason the methods I am using should be incompatible with PLA however.

The mounting plate is just a dummy part acting as a placeholder for a proper mounting design. I plan to use this same extruder mechanism to get the Gemini 3D Printer up and running soon.

There are a few more new parts for the K03 that I am currently building to refine the linear mechanism and then I’ll get the new parts going for the Gemini to attach a pair of these – the current extruder motor mounts won’t be compatible. I didn’t have an extruder design when I came up with them initially, but I digress.

I should also note that all of the above printed parts where made on the current Kitchissippi Delta prototype.

Now that the entire delta mechanism and effector are satisfactory, my testing has shown that the linear carriage design is a bit wanting. The mechanism I designed over a year ago has too much flex in it which allows it to rock a little bit from the forces of pushing around the delta arms.

The net result of this is a very slight tilting of the effector while printing. In practice it’s had negligible effects on the ability of the machine to make an accurate print, but the overall quality is not quite up to par with my well-tuned Mendel.

Ultimately I’d like to have the whole machine parametric and scripted in OpenSCAD anyway, so making new linear carriages is a logical next step. A detailed description of the carriages will follow when they are complete and I have some more time.

The basic gist of the new design is that the carriages now have an offset between the upper and lower bearing clusters to improve stability and the spacers are now utilizing 17/32″ rubber plumbing washers which I hope will provide better adjustability and a tighter fit to the steel tubing without forcing the bearings to gouge it.

Finally, here’s another teaser print from the Kitchissippi-Delta in it’s current form:

Recent Comments