by B Cantin | Mar 26, 2015 | Gemini 3D Printer

Although there is some work to be done still in terms of getting everything configured within the Smoothieware so that the Gemini 3D printer is working optimally, it’s already proving itself capable of making some nice prints:

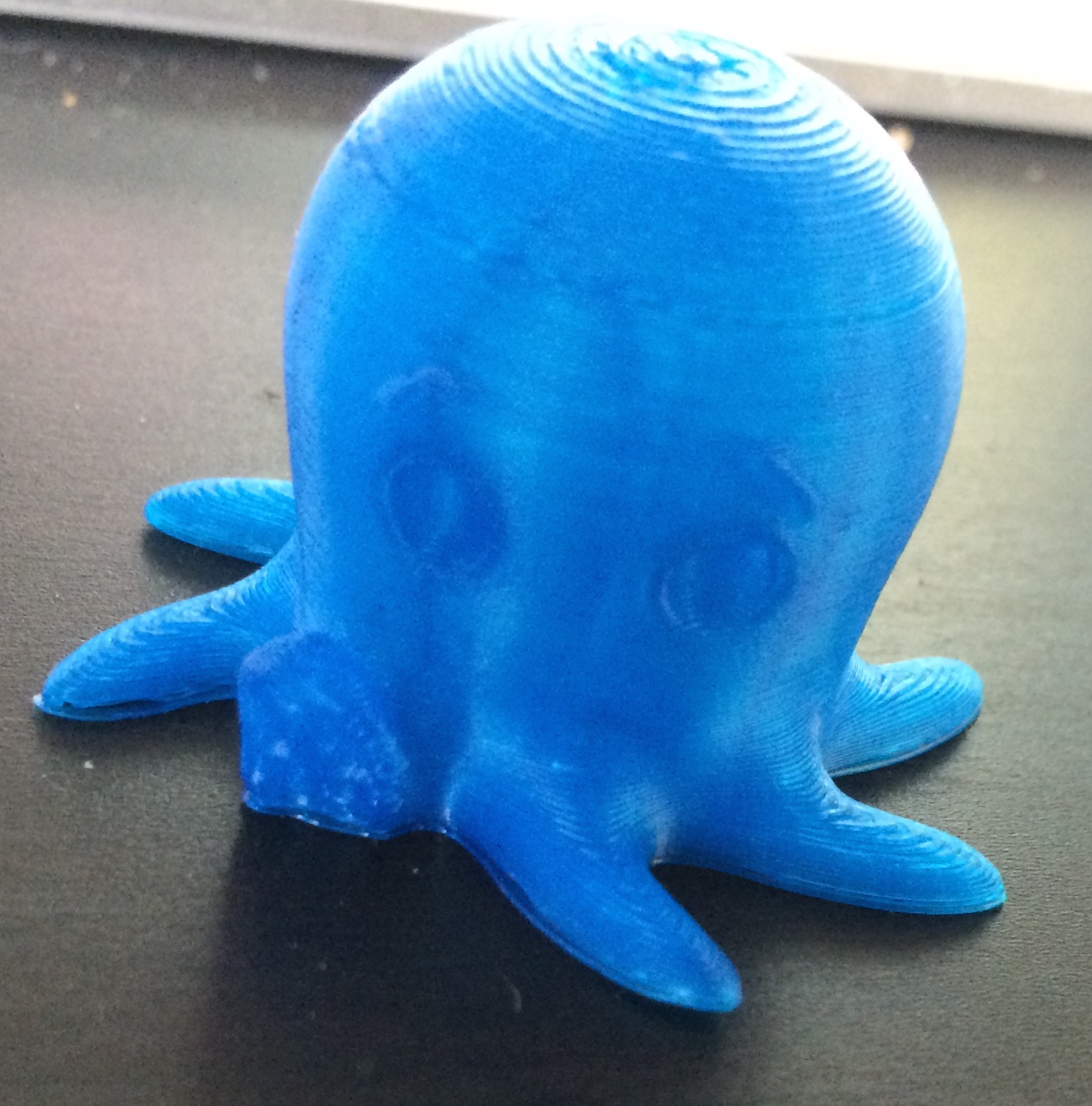

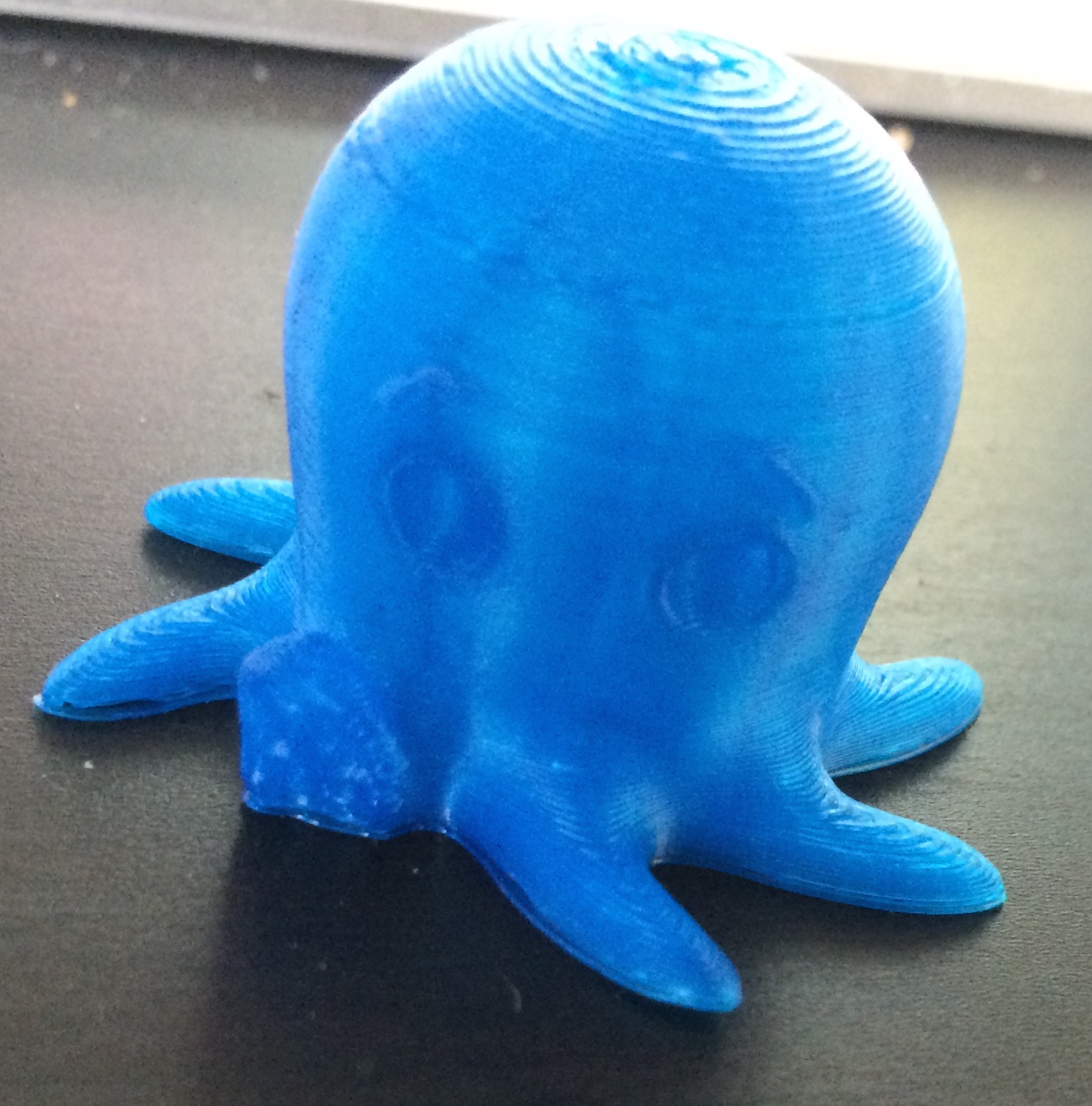

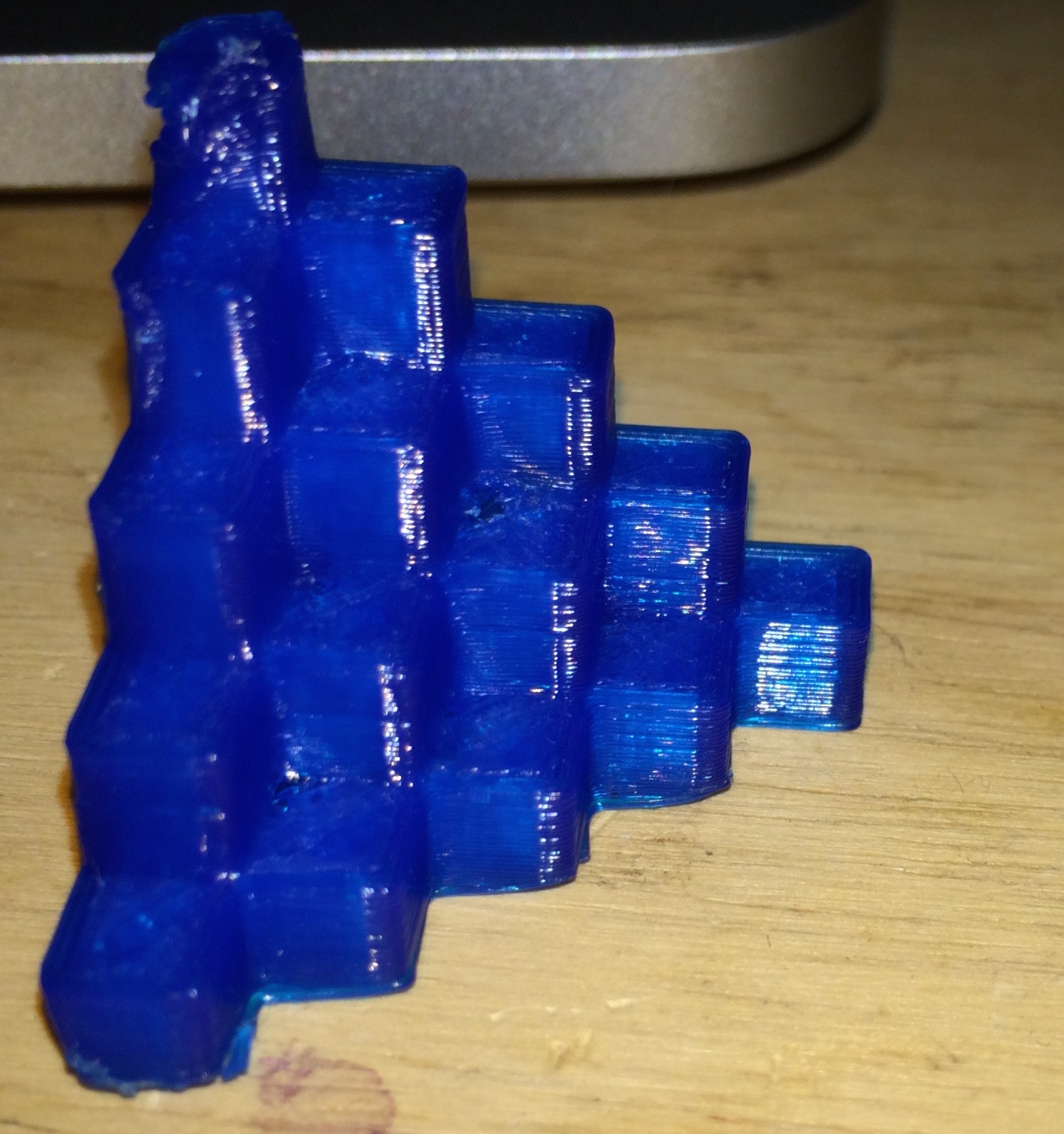

This little guy was scaled down to reduce print time at the low test speeds I’ve been working at initially. This was done using a sky-blue 1.75mm PLA with 10% infill, 0.2mm layer height and 30/mms speed.

On my Mendel i2 printer the outer perimeter speed needs to be printed slower than the interior perimeters and infill in order to produce such a smooth outer layer – the Gemini required no such consideration, clearly demonstrating the benefits of the corexy movement and linear rails.

There is a slight layer glitch near the top – this was caused by the laptop controlling the printer going to sleep state. I was nearby and was able to resume the print quickly, however it did produce an artifact on that layer as a result.

At higher speeds there are some issues with the acceleration settings within the configuration file as well as some serious drawbacks to the filament pusher design. I’ll be working on increasing speeds and then designing my own extruder for the printer to resolve these issues and get the machine running at it’s true potential.

by Brian Cantin | Mar 25, 2015 | Gemini 3D Printer

As with all printers, after assembly and initial electronics testing, it becomes time to print calibration cubes.

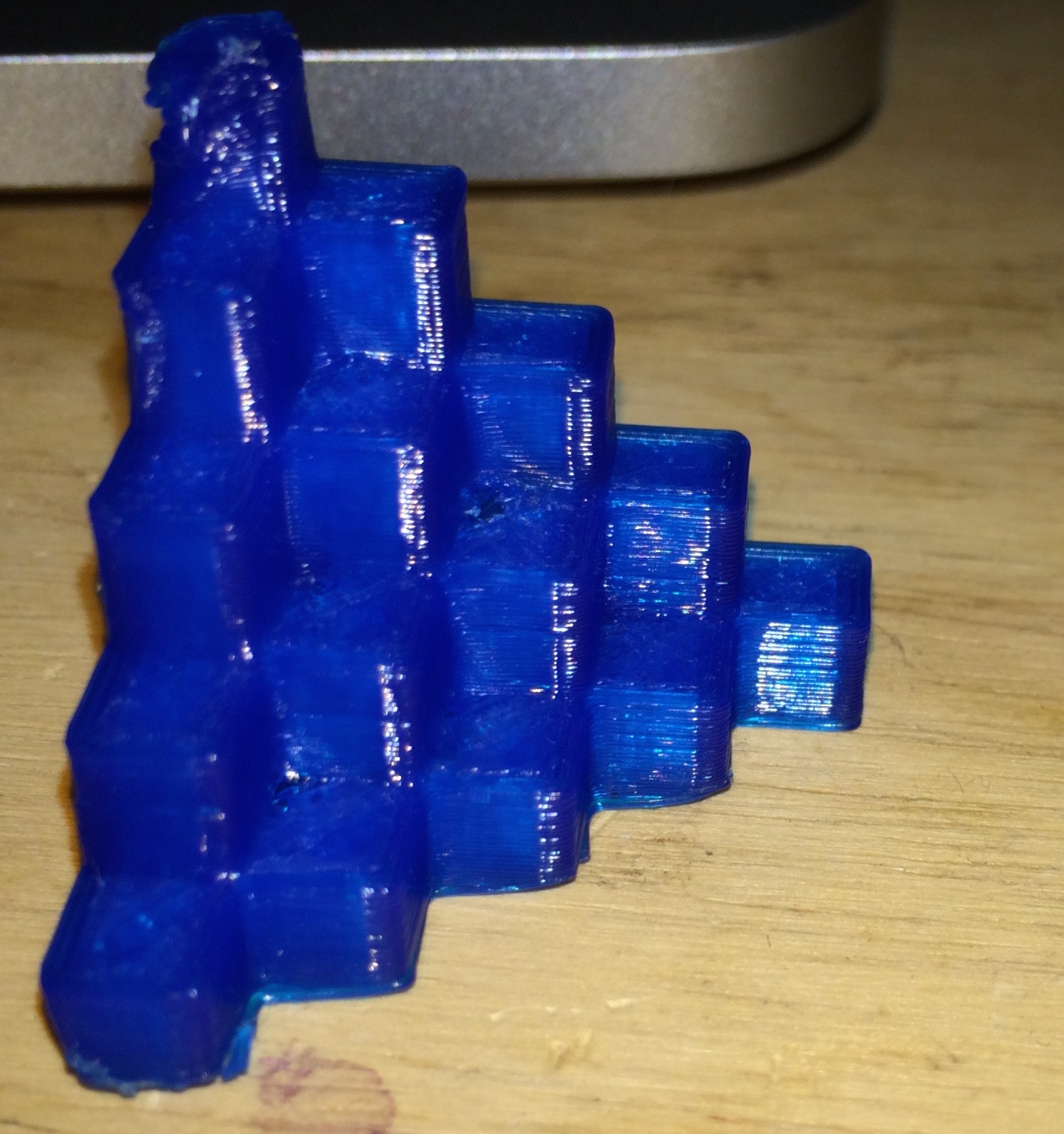

This simple step cube came out fairly well, especially when you consider that I made a mistake when slicing it in Cura and forget to put in any infill.

Since I was testing the extruder and some other factors out at the same time, I decided to let it run and was pleasantly surprised by the machine’s ability to bridge the PLA and create the shape despite having no infill to support the next row of cubes.

One thing that is evident is that the blower that is channeled through the bottom of the x-carriage assembly is definitely doing it’s job, but needs a slight modification in range of the print it blows across. Note the top tiny cube is fairly straight on the right side, but melted and distorted on the left side.

This is due to the blower only cooling the print from the right, the left side blower is beside the other nozzle and unable to cool the plastic on that side.

Some redesign of how that works will be needed.

As a side note from the testing done last night, I will eventually need to move away from the modified AirTripper style extruder to something more custom for this machine. Higher print speeds causes the filament to kink within the gap between the pinch roller and the pneumatic fitting and jam up the whole works.

by Brian Cantin | Mar 20, 2015 | Gemini 3D Printer

Just a quick note that partial documentation on the Kitchissippi Gemini 3D Printer is now online here.

As the parts finalized for the current build they will be listed and displayed in the Printed Parts section.

Some items for the Bill of Materials section will be put online within the coming days, mostly generic things like the necessary stock of certain metric bolt sizes and the 2020 aluminum extrusions used for the frame which is unlikely to change any time soon for this build.

As always, any questions can be addressed to novakane on the freenode #reprap IRC channel.

by Brian Cantin | Mar 19, 2015 | Gemini 3D Printer

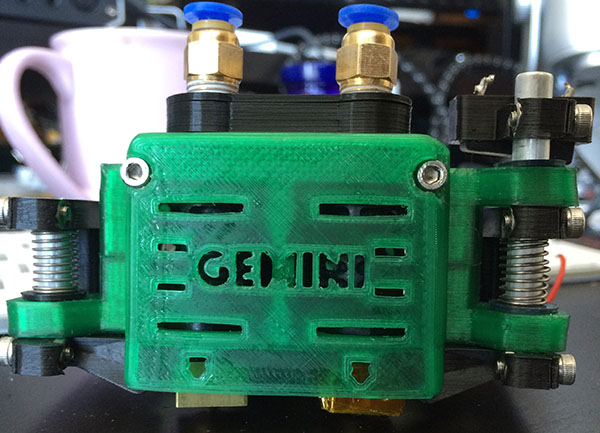

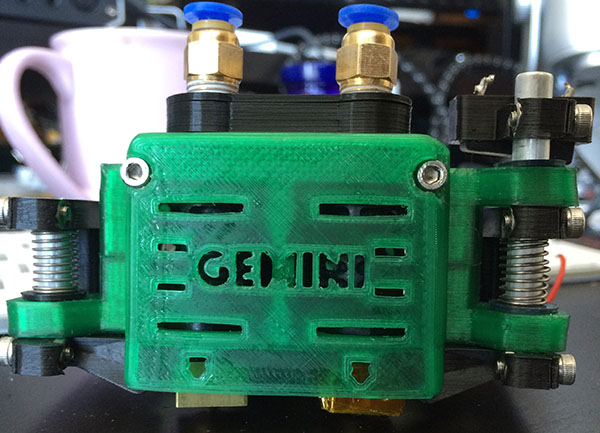

This is really the trickiest and most unusual component in the Gemini 3D printer.

A lot of parts need to be assembled into a small space to pack all the hotend electronics into a chassis that can move smoothly and consistently.

Some of the features of the chassis design:

- 2x 0.4mm nozzle J-Head Mk V-BV hotends (from hotends.com)

- 2x 12v 25mm fans for cooling the fins in the PEEK portion of the J-Head (software controlled, triggered by hotend temperature)

- 2x Pneumatic pushfit connectors to fit 2mm ID/4mm OD PTFE tubing for bowden style extrusion

Thes features are new or improvements over the initial proof-of-concept prototypes:

- 3-point vertical sliding mechanism, spring loaded and running on PLA bushings. The guide rods are polished aluminum.

- Bolt-clamps for the aluminum rods.

- Fans are enclosed for better forced-airflow through the J-Head vents, and reduced air leakage towards the heating blocks

- Ducted air channels for targeted print cooling. The 12v high-CFM blower fan is mounted on the rear of the X carriage (not pictured)

- 1x Z endstop microswitch – when the primary (right) nozzle makes contact with the print bed, this triggers to inform the firmware that the print bed height has been found. It is manually adjustable by loosening the clamp bolt and sliding it up or down the guide rod. This design puts the switch even more inline with the motion of the chassis that the prototype models and allows the design to be more compact.

- By integrating the fan mounts, and hotend groove mounts together the design is easier to print and assemble, as well as being sturdier.

- pushfit bushings allow for easy replacement and reduces the complication of previous prototypes.

This chassis assembly will require some minor revisions to the existing X carriage mounting system. Although the M4 bolts are spaced the same as previous prototypes, the assembly mounts lower on the carriage.

More work still needs to be done on the X carriage, but this hotend chassis is a fairly stable design now and will soon be merged into the master git source.

by B Cantin | Mar 12, 2015 | Website

Kitchissippi Robotics is proud to announce that our website is now online. The contents are being fleshed out, check back soon!

Recent Comments