Kitchissippi Gemini 3D Printer

Project Description

This is an in-progress design for the machine – the source may change frequently and is not currently stable. Any questions can be directed to novakane on the freenode IRC channel #reprap

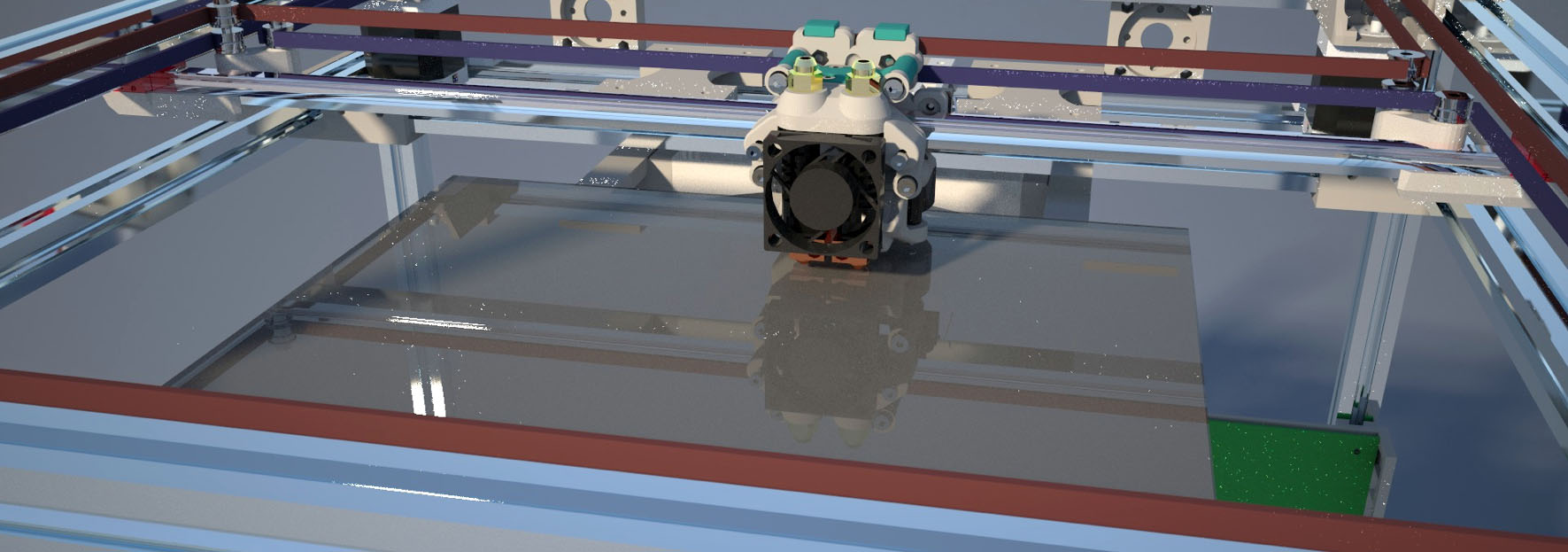

The Gemini is a CoreXY based 3D printer with dual extrusion capabilities and a large print volume. The machine is capable of depositing layers of filament from both extruders over it’s full print volume of 300mm x 300mm x 400+mm.

Initial object models were designed to minimize initial print time; test the underlying design theory; and finally, identify stress points in assembly. This makes the parts more fragile than a production model, however the initial K02.2 prototype successfully made several prints of decent quality. Most print failures may have been explained by early bed mounting and filament pusher mounting – these were done mostly as hacks to test the electronics and basic mechanism.

Current design work is aimed at producing a more robust mechanism with a polished look and feel.

Dual Material Printing

Many 3D printers can only deposit a single material per print. This limits the shapes of objects you can create without using difficult to remove same-material supports. Same-material support requires greater effort in post-print finishing and is impossible to use internally within an object.

With a second extruder you can use dissolvable filament such as HIPS or PVA which makes post-print removal of support material easy and clean.

Newer materials such as electrically conductive or carbon fibre filaments open up a world of possibility to embedding dissimilar materials within each other in the same print.

The Kitchissippi Gemini 3D Printer aims to make these possibilities a reality.

Large Volume Printing

Typical consumer 3D printers can only make small objects due to their limited print bed size and physical limitations. Scaling many of them up to the size of the Kitchissippi Gemini 3D Printer will introduce speed penalties due to the increased moving mass.

The larger the print area, the faster you want to be able to print to cover the increased volume. It is counter productive if the machine has to slow down to accommodate a larger mechanism.

The Kitchissippi Gemini 3D printer is scalable without compromises – the base prototype has a 300mm x 300mm print area with very little moving mass, allowing it to produce large objects in less time. The print bed itself only moves once per layer, vertically driven by precision lead screws. Only the extruder carriage is in constant motion and the heavy stepper motors for pushing the filament remain stationary.

CoreXY Linear Motion

Although there are many ways to achieve a stationary XY gantry, the Kitchissippi Gemini 3D Printer uses the CoreXY concept.

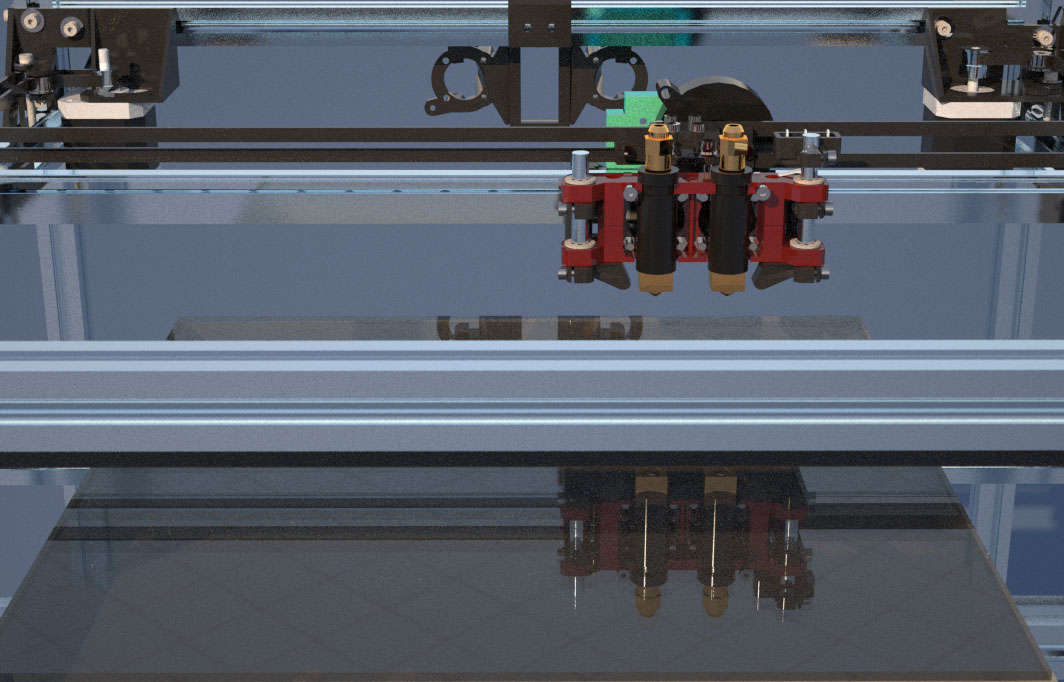

Instead of moving heavy hardened steel rods, the Gemini uses light-weight 9mm miniature linear slide rails which provide smooth but rigid linear motion. CoreXY eliminates the potential binding issues seen with HBot designs allowing for large-span guides without the bulk.

Recent Blog Entries

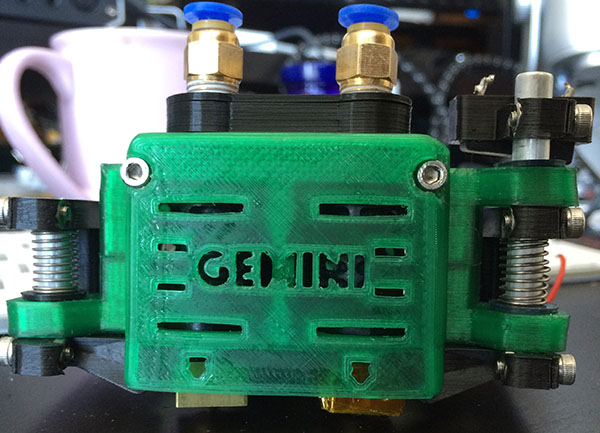

Reconsidering the Gemini Hotend Chassis

The hotend chassis in use on the current Gemini 3D Printer prototype is fairly successful. It works and proved to be an interesting thought exercise to get it to a serious level of functionality. I have been considering some of the drawbacks however and going back to...

Need for Speed

After getting several good prints while tuning the Z height detection mechanism that is the core reasoning behind complicating the Hotend Chassis of the Gemini printer, I started working on the Smoothieware settings that seemed to be causing some grief when attempting...

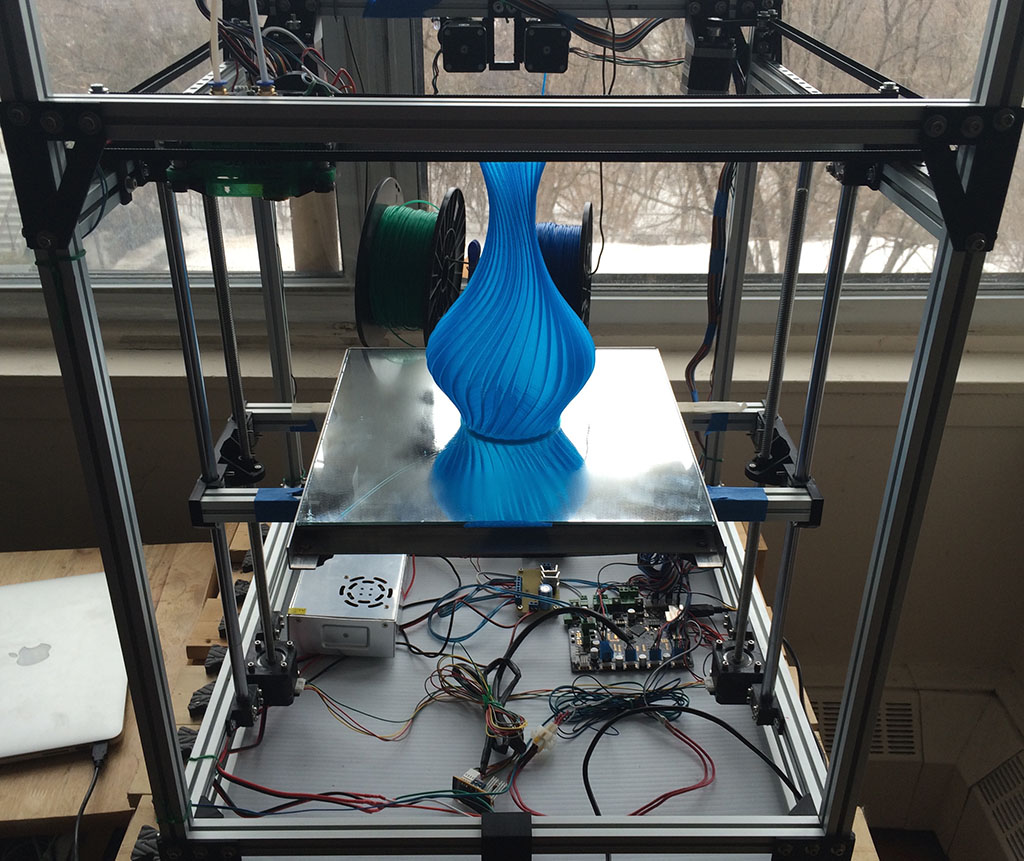

Big Vase Prints – Not Just for Deltas

After rebuilding the extruder's filament pusher three times due to it's penchant for ejecting the pneumatic pushfit connector, I was finally able to get it to behave, at least at lower speeds. I'll be designing my own instead of using an existing design at some point...

First nice test print

Although there is some work to be done still in terms of getting everything configured within the Smoothieware so that the Gemini 3D printer is working optimally, it's already proving itself capable of making some nice prints: This little guy was scaled down to reduce...

Calibration Cubes

As with all printers, after assembly and initial electronics testing, it becomes time to print calibration cubes. This simple step cube came out fairly well, especially when you consider that I made a mistake when slicing it in Cura and forget to put in any infill....

Start of Gemini 3D Printer Documentation

Just a quick note that partial documentation on the Kitchissippi Gemini 3D Printer is now online here. As the parts finalized for the current build they will be listed and displayed in the Printed Parts section. Some items for the Bill of Materials section will be put...

New Dual Nozzle Hotend Assembly with Z Probe

This is really the trickiest and most unusual component in the Gemini 3D printer. A lot of parts need to be assembled into a small space to pack all the hotend electronics into a chassis that can move smoothly and consistently. Some of the features of the chassis...