Kitchissippi Delta

Project Description

The Kitchissippi Delta is a prototype delta style 3D printer designed by Brian Cantin.

The early versions have proven that the concept works well, however it requires refinement.

This page (much like the printer) is a Work-in-Progress – check back soon for more updates.

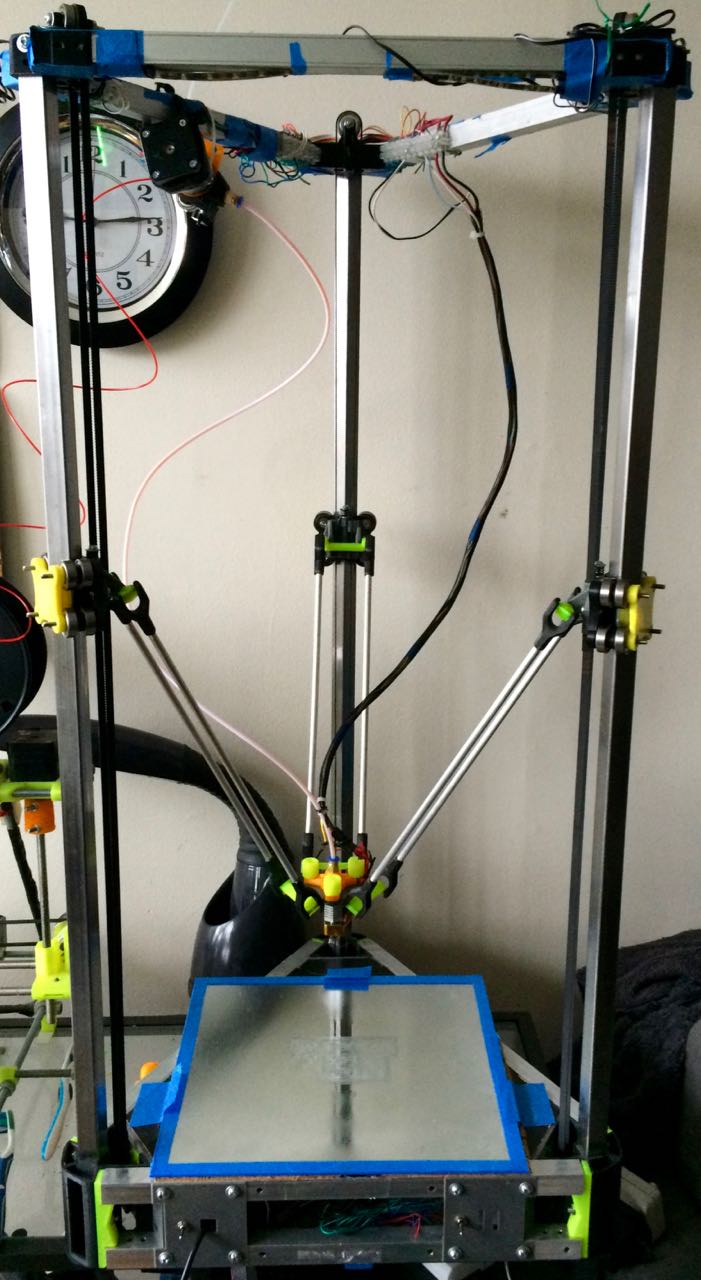

The above picture shows the working prototype as of March 14th, 2016. It is making nice prints and is missing a few minor features such as the front-panel LCD mounting brackets, a filament spool holder and a proper mount for the extruder motor.

Project Details

Kitchissippi-Delta project on GitHub.

Parametric Design

As of mid-February of 2016 work has been underway to cleanup the GitHub source for the Kitchissippi Gemini 3D printer and rebuild the core mechanics using OpenSCAD.

The fame design remains unchanged from the previous version which was created entirely in SketchUp. It’s a working design so no effort will be put into that portion of the build in v3.2, with the exception of the top frame/idler assemblies.

Easily Sourced Linear Guides

The primary uniqueness of the Kitchissippi-Delta lies in it’s linear guide mechanism. Early delta designs such as the Rostock used hardened steel rods as both the frame and linear guides. The disadvantage to this becomes clear when scaling the design to make a larger printer – these rods are expensive and need to made increasingly thicker the longer they become in order to avoid flexing and ultimately the frame typically needs additional supports added.

Newer delta designs replace these rods with extruded aluminum t-slot (or v-slot) and specialized bearings which can be quite difficult to source and rather expensive in some locations.

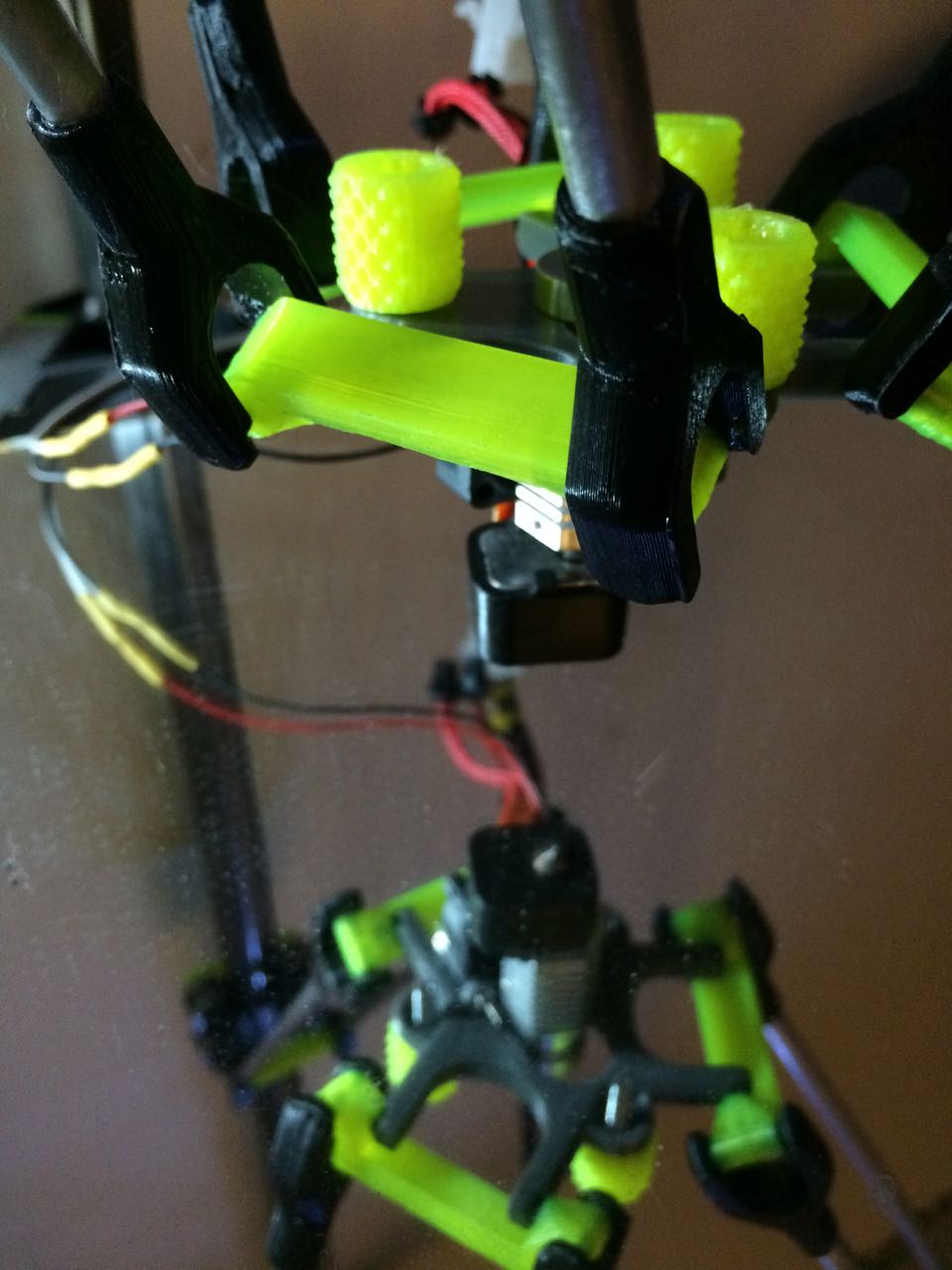

During earlier experiments in linear motion I came up with a design that uses a set of eight low-cost 608zz skate bearings constrained around a common square steel tube at a 45 degree angle. This provides smooth linear motion on a scalable level which uses components that are easily sourced for low cost.

This linear guide design has gone through several refinements but has proven itself to be up to the task of providing both the frame uprights as well as the linear guide quite effectively. The latest revision has adjustable tension courtesy of rubber spacer washers which provides smooth linear motion and stable guiding of the delta mechanism throughout it’s range of motion.

You can read more about the evolution of the linear carriage design on this blog post.

Low-Cost Snap-Fit Joints

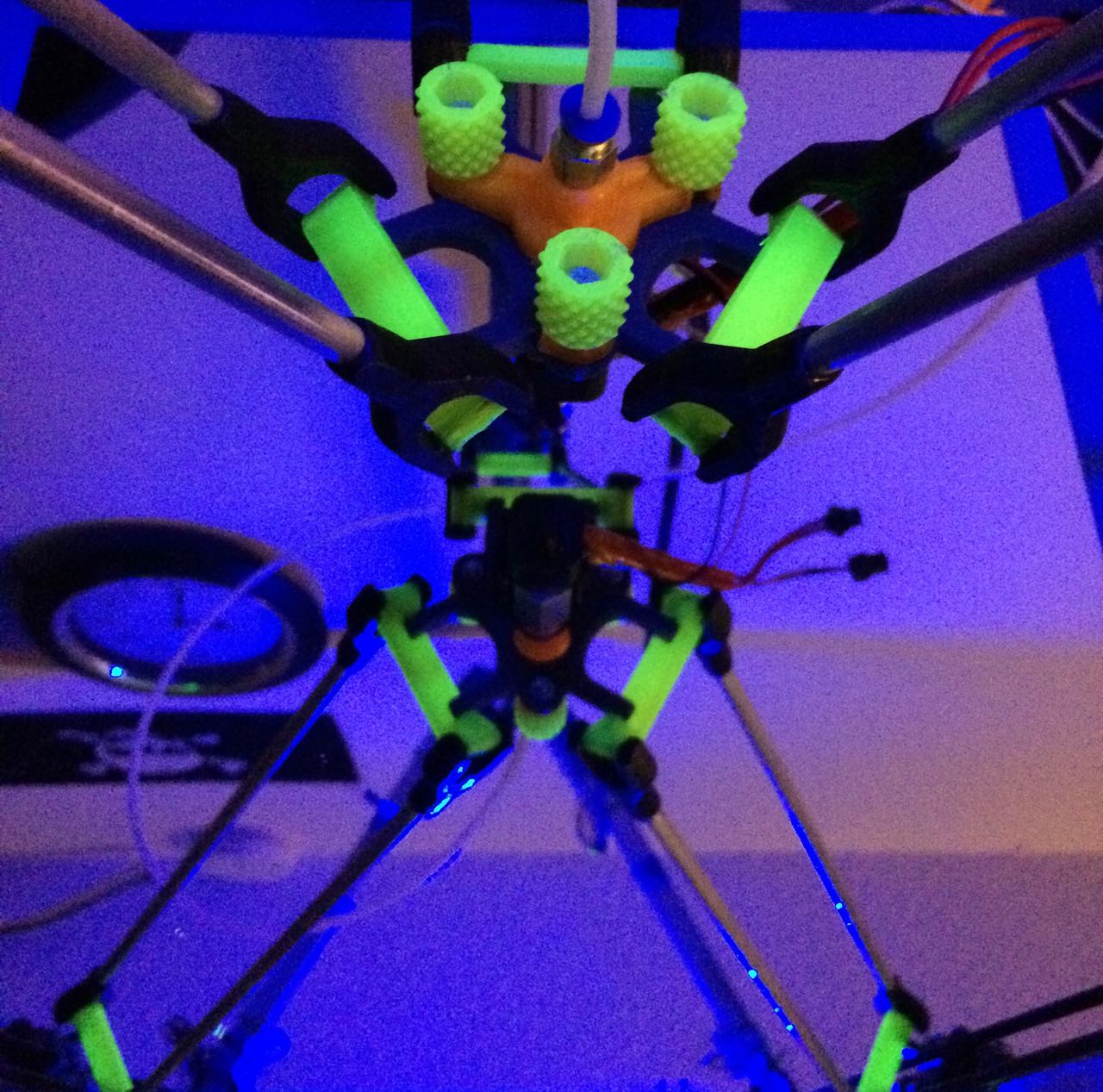

One of the key aspects of the Kitchissippi-Delta 3D Printer is it’s goal to reduce the number of specialized parts required to create a delta style printer. Many delta designs use rare-earth magnets, or Traxxas joints from RC cars, but the Kitchissippi-Delta has a unique system that uses a combination of hardened steel pins extracted from common bicycle chains and 3D printed sockets.

The previous prototypes proved this concept works, although the initial implementation was flawed and prone to slop which necessitated very conservative jerk settings and low print speeds to prevent inaccuracy in the print quality.

The revised parametric version of these mechanics introduces a significantly more stable and easier-to-use snap fit construction which virtually eliminates all of the play within the previous joint design and is vastly easier to repeatedly disassemble and reassemble for servicing of the mechanism.

Recent Blog Posts

Kitchissippi-Delta – Improved 45 Degree Carriage Design

As I detailed in my last post - The Kitchissippi Robotics 45 Degree Linear Carriage (A brief history) my unique linear carriage design has gone through off-and-on revision and evolution over the past two years or so since I first came up with the idea. The latest...

The Kitchissippi Robotics 45 Degree Linear Carriage (A brief history)

This linear carriage design is something I have been toying with for several years now. It all started with having picked up a bulk lot of 608zz skate bearings with the intent of making a Rostock or similar delta printer some day, but mostly because I needed a few for...

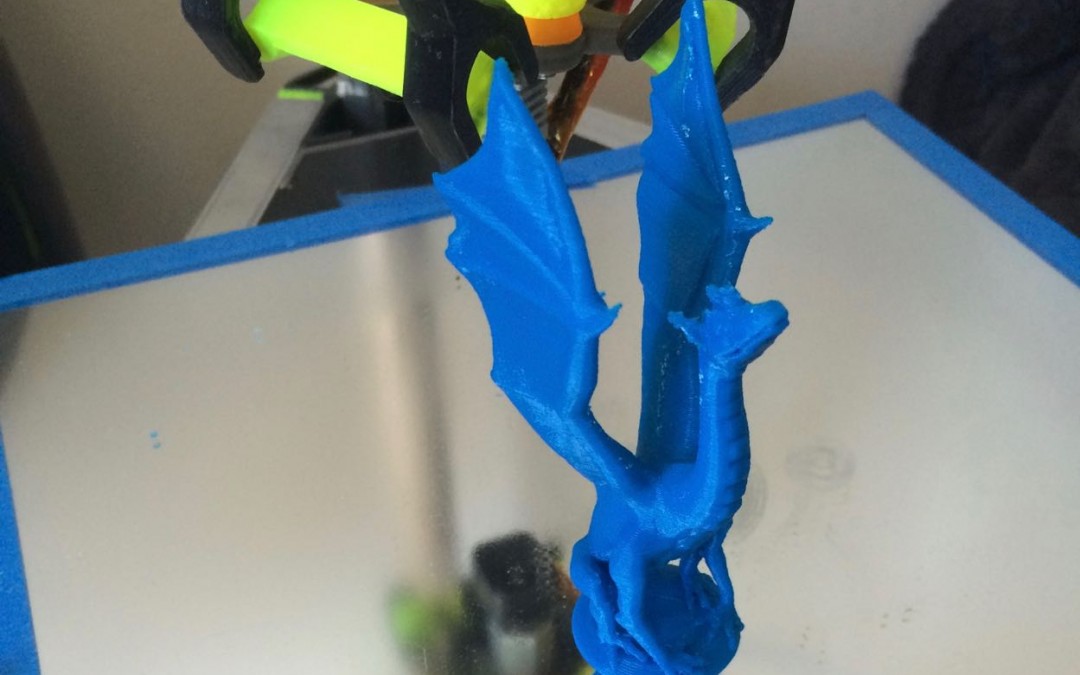

Kitchissippi-Delta Up and Running

It's been a busy week so I've not had time to detail my progress, but my K03 - Kitchissippi Delta 3D Printer is back up and running and better than ever with the newly designed OpenSCAD parts. Here is the new effector assembled with the new swivel joints and push fit...

Kitchissippi-Delta Epoxy Curing

As I described yesterday evening, I have made new rod-ends for the Kitchissippi-Delta and the 5-minute epoxy seems to be anything but 5 minutes for curing time. Twelve hours later the joints seem quite strong but are not quite hardened yet. I am pretty certain that...

Kitchissippi-Delta Rod Ends / Clevis Joints

As my previous post discussed, I had some inspiration this week as to how to resurrect the Kitchissippi-Delta 3D printer from it's previous self-destruction. I have no doubt of the issue with the mechanism skewing could have been avoided by using a better adhesive to...

Kitchissippi-Delta Mechanism Redesign

One evening last year the glue holding on the rod-ends on the original Kitchissippi-Delta prototype slipped due to a head crash skewing the mechanism and causing a subsequent further crash of the effector into the build platform. Not only did this shatter the glass...